Abrasive - blasting

Surface finishing

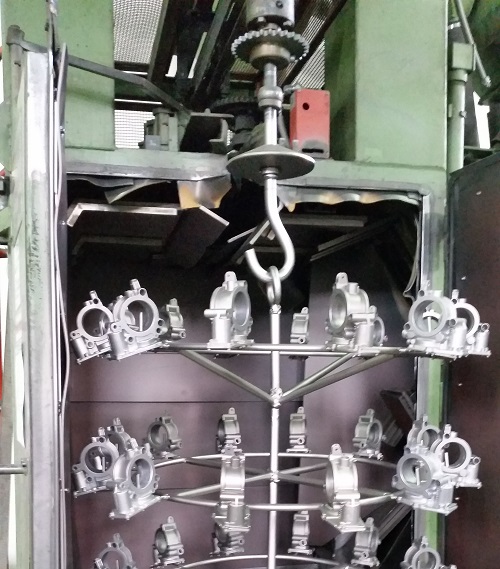

Automatic centrifugal wheel type blast cleaning and shot peening machine for surface treatment operations.

Blasting media

The blasting media used in this case was composed of metal shots CrNi30 and it was selected in strict conjunction with the application and the required results.

Blasting process

The actual blast cleaning or shot peening process is conducted completely automatically. Workloads are initially introduced into the blasting machine. 3 rapidly rotating centrifugal wheels bombard each workload with tremendous amounts of media grains representing an enormous number of impacts.

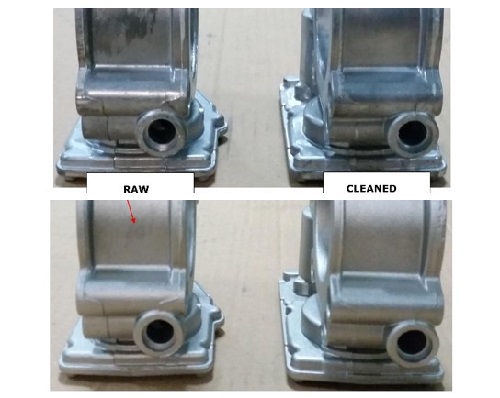

Preparation before blasting

Some components must be cleaned before blasting, in order to remove any residues of grease from the casting process, otherwise the impurities will be fused to the surface.

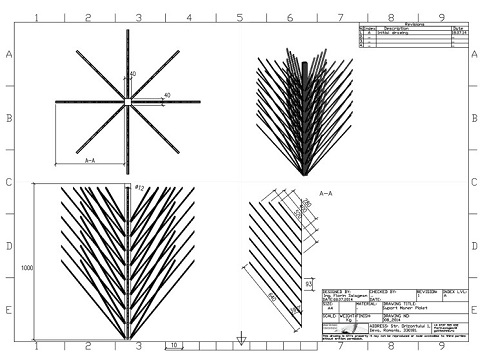

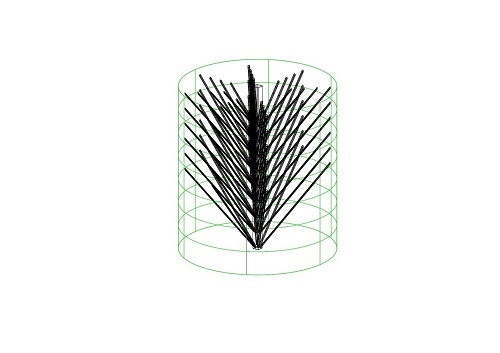

Dedicated hanger

For process optimisation and lowering the cost, we design and produce special hangers based on the shape and size of your part.

Blasting chamber

Working height and diameter of the blasting machine.

H = 1000 mm; D = 950 mm.

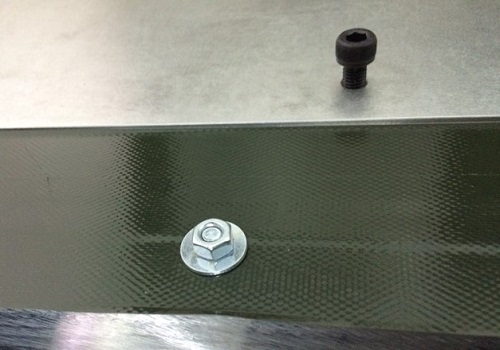

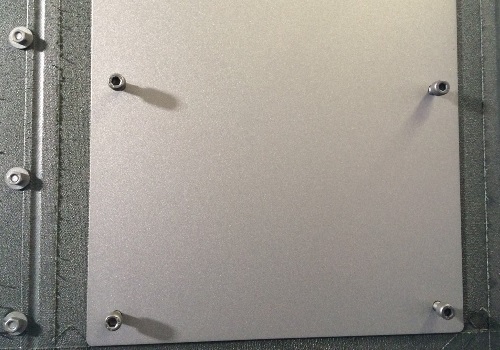

Partial blasting

We can protect parts of components that don’t require blasting.

Protected blasting

Some parts are machined before blasting, those tolerances will not be affected if they are properly protected.

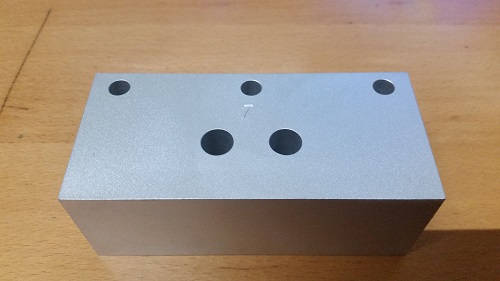

Complex parts

For increased roughness another blasting machine is used, 2 rapidly rotating centrifugal wheels bombard each workload with tremendous amounts of media grains representing an enormous number of impacts.

Increased roughness

The blasting media used in this case was composed of metal shots CrNi40 and it was selected in strict conjunction with the application and the required results.

Tumbler machine for deburring

Tumblers are machines that hold many parts as well as some type of wet or dry media. The tumbler will rotate like a mixing drum on a cement truck to work the media and parts around. In doing so, the tumbler along with the chosen media buffs away the burrs. There are many different types of media that must be considered when thinking of deburring; examples are plastic media, corn cob media and ceramic media. These are used in concordance with deburring machines in order to rid parts of burrs.

Blast cabinet

A blast cabinet is essentially a closed loop system that allows the operator to blast the part and recycle the abrasive.

Small imperfections

Manual abrasive blasting is a service that we provide for a finer surface or for correcting small imperfections.

Finer surface

The blasting media used in this case was composed of glass beads.

Galli Technic International

The future is not a gift, it is an achievement.

Contact Info

Address: Str. Portului, Nr. 2, Deva, Hunedoara, Romania, 330181

+4 0254 212 110

+4 0737 233 590